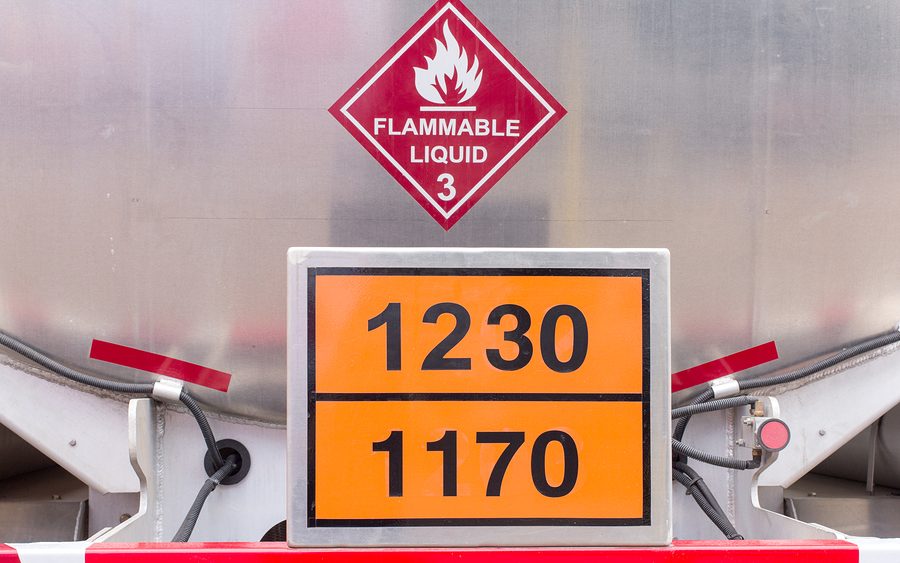

Last time, we talked about placard loads in transport, and what you need to do to transport goods by road.

Of course, any hazardous goods you work with will probably probably only be in transit when you’re taking a delivery or shipping one out – all the other times, it’ll be in storage, awaiting use.

And while they’re in storage, they’ll need to adhere to strict placarding requirements just like when they’re being transported.

What types of placards do you need? Where should placards be put up? What types of signs do you need?

Today, we’ll be answering all of these questions and more.

What does placarding mean? What is placarding for dangerous goods?

Essentially, it’s all about hanging up the right dangerous goods warning signs and dangerous goods labels if your business deals with hazardous chemicals and substances.

After all, these substances can be:

- Harmful to health and wellbeing

- Damaging to the environment

- Hard to clean up in the event of a spill

- Fire and explosion hazards

As such, it’s important that you take measures to ensure that your team is aware of the risk, as well as what they need to do to minimise their risk.

There are a lot of different moving parts – however, it all starts by ensuring that you’ve got the right signage and placards in place.

When can dangerous placards be used?

It can be hard to decide which substances are dangerous enough to warrant placarding, especially if you don’t have anything to go off of.

Luckily, you don’t need to resort to guesswork.

The GHS (which Australian laws are based off) identify the different types of chemicals and substances that require dedicated signage and placarding to stay safe.

If the substances you work with are listed there, you’ll need appropriate signage and placarding, simple as that.

The only times when you don’t need hazchem signs are if:

- The chemicals in question are consumer-grade, and in quantities consistent with consumer use

- They’re veterinary or agricultural chemicals (these have their own rules guiding them)

- The chemicals are for cosmetic usage (such as hairspray and bleach)

If it doesn’t fall into one of these categories, then you’ll need placarding and signage to keep everyone safe.

Where should placards be placed?

Common sense says that chemical storage areas and cabinets need to be identified using placards and signs, while containers should be labelled whenever possible.

However, these aren’t the only places you’ll need to hang up placards.

According to section 4 of the national WHS regulations, businesses and workplaces are also required to display placards and signs at entrances as well as inside, with exceptions made for petrol stations (those are self-explanatory) and retail outlets.

Of course, this isn’t the only concern when it comes to placing placards – it’s also important that said placards and signs are visible to your team.

That means:

- Minimising obstructions

- Ensuring that signs are legible from regular working distances

- Compensating for lighting conditions

- At an appropriate height

Long story short, there are a lot of different things you’ll need to think about when it comes to placing safety signs and placards, not all of which are immediately obvious.

Luckily, since our team specialises in safety signs in Australia, this is something our team can help you out with!

How many placards are required when carrying hazardous chemicals?

You can never be too careful – of course, you also don’t want to overdo it, as placing too many unrelated signs next to each other can cause confusion.

So, what’s the sweet spot?

Truth be told, it all depends on your workplace. The chemicals you work with, how your place is laid out… all of this and more influences how many signs will need to go up at your property.

As a general rule however, you’ll want to ensure that each separate hazard gets its own sign.

For example, if you work with flammable gasses and liquids – both will need separate signs. That’s because while they’re both flammable they’re still fundamentally different substances which are flammable under different conditions.

And as such, they’ll need separate signs.

In many cases, you might need multiple signs to communicate the dangers associated with a particular substance or chemical – for example, you might need to combine hazchem signs with GHS signs and mandatory PPE signs to keep everyone safe.

Which is a concern for the loading and unloading of dangerous goods?

So far, we’ve been focusing on placarding for chemical storage.

If you work with hazardous goods and chemicals however, then you know that the most dangerous time is actually when you’re loading and unloading them.

Assuming you’ve got a good setup with proper ventilation and appropriate cabinets and containers, you probably won’t need to worry too much about an accident happening (not that you should

But when your loading and unloading them however, it’s a different story.

Now they’re being moved around, knocked about and more, all of which increases the likelihood of something going wrong. What if:

- A container is dropped?

- A lid pops off?

- The container is loaded/unloaded the wrong way?

A lot of substances are extremely sensitive, and have special handling requirements – that might mean special containers, or simply being extra cautious to make sure theta ren’t dropped.

Whatever it is, the details will be listed in the substance’s safety data sheet (SDS).

These are documents that are mandated by the GHS that list out all of the information about the substances you’re transporting or working with, including:

- Hazchem classification

- Fire risk

- Required PPE

- Risks to health

- Environmental impact

- Spill containment

- Storage and ventilation requirements

And most importantly for you at the moment, it also lays out how they need to be handled while loading and unloading them.

When a shipment comes in, suppliers are required to provide an SDS, especially if it’s your first time dealing with said substance. Be sure to go through this before you start unloading your chemicals and substances.

And if one hasn’t turned up, be sure to get on the line with them to request one!

Get the signs you need to stay safe

When it comes to placarding your dangerous chemicals and substances, the first step is to begin by taking a look at what signs you need.

Understanding your signage requirements is important – just as important is buying the right signs.

Unsure what you need? In addition to stocking one of the biggest ranges of hazchem signs in Australia, our team can also help you get exactly what you need.

Our workshop specialises in creating custom safety signs in Australia, helping you get the signs that you need for your placarding requirements.

Moreover, we’re more than happy to use our understanding of hazchem signage requirements to ensure that your signs are 100% compliant, and that you haven’t missed a single thing.

Find out how we can help you by calling (03) 9687 3050, or by clicking here to get in touch.

Alternatively, you can click here to start shopping from our range of pre-made signs.